CRC Intake Valve Cleaner vs Seafoam: Which Works Best?

When comparing CRC Intake Valve Cleaner vs Seafoam, CRC GDI IVD Cleaner is more effective for direct-injection engines suffering from intake valve carbon buildup, thanks to its PEA-based formula. Seafoam, on the other hand, is a versatile fuel and oil additive that works best for general maintenance and preventing deposits.

Quick Comparison Table

| Feature/Factor | CRC GDI IVD Cleaner (Intake Valve Cleaner) | Seafoam Motor Treatment / Spray |

|---|---|---|

| Primary Use | Targeted carbon buildup cleaner for GDI intake valves | Fuel, oil, and intake cleaner additive |

| Best for | Modern GDI (Gasoline Direct Injection) engines | Older engines, preventive maintenance |

| Application Method | Aerosol sprayed into throttle body (engine running) | Pour into fuel/oil or use Seafoam Spray via vacuum line |

| Cleaning Strength | High concentration PEA-based cleaner | Mild, petroleum-based solvent |

| Price Range | $8–$12 per can | $7–$10 per can |

| Effectiveness | Excellent at removing hardened deposits | Good for preventing carbon buildup |

| Ease of Use | Requires RPM control and correct spraying | Easy “pour & go” or vacuum spray method |

Why Intake Valve Cleaning Matters (Especially for GDI Engines)

In GDI (Gasoline Direct Injection) engines, fuel no longer washes over the intake valves. This leads to hard carbon deposits forming on the intake valves and combustion chamber walls. Over time, these deposits restrict airflow, reduce fuel efficiency, and cause rough idling.

That’s why car owners search for the best intake valve cleaner—products like CRC GDI IVD Cleaner and Seafoam Spray Intake Valve Cleaner are designed to tackle this issue, but they work differently.

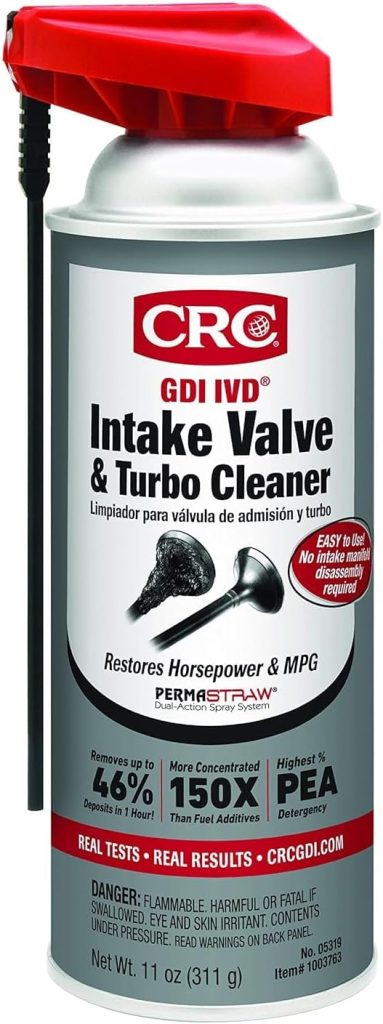

CRC Intake Valve Cleaner: Deep Dive

CRC’s GDI IVD Intake Valve Cleaner is a PEA-based carbon buildup cleaner specifically engineered for direct-injection intake valves. Unlike traditional fuel additives, it’s sprayed directly into the throttle body so it can contact the valves directly.

Key Benefits

- Aggressive Carbon Removal: Proven to dissolve stubborn intake deposits in one treatment.

- PEA Formula Advantage: PEA (polyether amine) is the most effective detergent for breaking down carbon.

- OEM-Recommended: Many manufacturers recommend CRC GDI cleaners for scheduled intake valve maintenance.

Downsides

- Application Complexity: Requires correct RPMs during spraying.

- Not Multi-Use: Strictly an intake valve cleaner, not a fuel additive.

- Safety Precaution: Strong chemicals—protective gear recommended.

Seafoam Motor Treatment & Spray: Deep Dive

Seafoam is a multi-purpose petroleum-based additive. It can be:

- Poured into the fuel tank (to clean injectors & combustion chambers)

- Added to the crankcase (to dissolve sludge/varnish in oil systems)

- Used as Seafoam Spray via vacuum line (for intake cleaning)

Key Benefits

- Versatility: Works in oil, fuel, and intake systems.

- Gentle Cleaning: Dissolves gum, varnish, and soft carbon.

- Ease of Use: Simple pour-in method for ongoing maintenance.

- Affordable: Widely available and budget-friendly.

Downsides

- Less Effective on Hardened Deposits: Not strong enough for GDI intake valves already coated in heavy carbon.

- Slow Results: Works gradually over time.

- Vacuum Spray Method: Can produce heavy smoke and requires care.

Performance Comparison: CRC vs Seafoam

1. Effectiveness on Carbon Buildup

- CRC Intake Valve Cleaner: Extremely effective on hardened deposits in GDI engines.

- Seafoam Spray or Additive: Good for preventing carbon buildup, but not strong enough for heavy deposits.

2. Ease of Use

- CRC GDI Cleaner: More technical application—best for DIYers with some experience.

- Seafoam Spray/Fuel Additive: Beginner-friendly and low effort.

3. Versatility

- CRC: Single-purpose, but very effective.

- Seafoam: Multi-purpose—fuel stabilizer, oil system cleaner, and intake cleaner.

4. Cost Efficiency

Both are under $15 per treatment. Seafoam offers more applications per can, while CRC is worth it for one-time intensive cleaning.

Real-World Use Cases

- Best for GDI Turbo Engines: CRC GDI IVD Cleaner is highly recommended for engines like Ford EcoBoost, VW TSI, BMW, Audi, Hyundai/Kia GDI.

- Best for Older or Carbureted Engines: Seafoam is perfect for dissolving varnish, sludge, and keeping injectors clean.

- Best for Preventive Maintenance: Seafoam added every few thousand miles helps maintain injector and chamber cleanliness.

- Best for Problem-Solving: CRC is the go-to intake valve cleaner once performance issues arise.

Expert Verdict: Which Intake Valve Cleaner Should You Choose?

- If you own a modern direct-injection engine with carbon buildup, choose CRC GDI Intake Valve Cleaner for a one-shot deep clean.

- If you want ongoing preventive maintenance across your fuel, oil, and intake systems, go with Seafoam Motor Treatment.

- Many enthusiasts use both together: CRC for periodic intake cleaning, and Seafoam as a regular system additive.

FAQs: CRC Intake Valve Cleaner vs Seafoam

1. Is Seafoam good for GDI engines?

Yes, but only for injectors and combustion chambers. It won’t clean GDI intake valves—CRC is better for that.

2. What makes CRC more effective?

Its PEA-based formula is engineered for hardened valve deposits, unlike Seafoam’s petroleum solvents.

3. How often should I clean my intake valves with CRC?

Every 10,000–15,000 miles or as part of scheduled GDI intake valve maintenance.

4. Can I use Seafoam and CRC together?

Yes—Seafoam for fuel/oil system upkeep, CRC for direct intake cleaning.

5. Which improves gas mileage more?

CRC may restore lost MPG in dirty GDI engines, while Seafoam helps maintain efficiency over time.

Conclusion

Both CRC Intake Valve Cleaner and Seafoam Spray/Fuel Additive play important roles in engine maintenance.

- Choose CRC GDI IVD Cleaner if you want a serious carbon buildup cleaner for intake valves in modern GDI engines.

- Choose Seafoam Motor Treatment if you need a versatile additive for regular system-wide cleaning and preventive carbon control.

👉 Best practice? Use Seafoam for ongoing maintenance, and schedule CRC treatments every 10K–15K miles for optimal intake valve performance.